Line Controller

The digital foreman for the production line

Your challenge

Traceability, smooth processes, and quick reactions to changing circumstances play an important role in today’s production processes.

Even after automation has taken place, inadequate information flows can remain between ERP/MES and the production lines.

This is a real productivity killer

-

For example, if recipes for the order must be transferred manually, this results in a low speed and high susceptibility to errors.

-

Traceability is also a major problem. Often there is no suitable feedback channel that provides specific production data such as:

-

Have the correct components been installed?

-

Has the production strictly adhered to correct process times, as for example with ventilating the primer during gluing?

-

Our solution

We bring intelligence into your (existing) line.

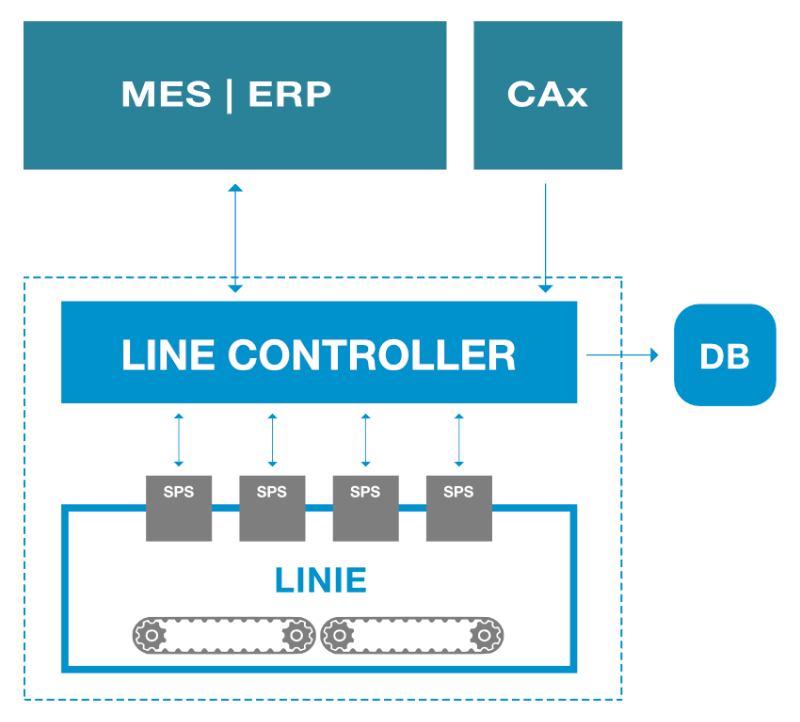

The Line Controller solution we have developed links your MES/ERP intelligently and individually with your production line.

In addition to pure data collection, it is possible to have a detailed process analysis. This reveals whether a change to the line has achieved the desired goal and even intervenes in production if necessary.

This monitoring function ensures that the quality of your products does not suffer and avoids defective production.

Our Line Controller solution also enables your employees to concentrate specifically on process monitoring. This reduces the susceptibility to errors.

Your advantages

-

Ensuring quality

-

Avoiding faulty production

-

Minimizing the recall rate

-

Ensuring traceability

-

Improved production processes and cost savings

Functions in detail

-

Management of production specifications

-

Management of orders, product variants, recipes, and process steps

-

Interaction with higher-level systems such as MES

-

Acquisition of process, product, and machine data

-

Production control through process analysis

-

Reporting and process visualization

-

Product data archiving

-

Complete product traceability

Features / interfaces

-

Adaptation to all interfaces you have described is possible

-

All interfaces common in the industry such as OPC-UA, S7online, XLR8 connection to Excel can be implemented

Your production is unique – so is our Line Controller.

No production is the same: benefit from our individual development and implementation processes.

We achieve the best results for you and successfully implement your objectives:

-

Detailed advice and – based on this – individual concept development

-

Selecting the right components depending on the current situation on site

-

Development & programming of your individual solution

-

Realization & implementation of the project

-

Documentation & quality control

-

Calibration, maintenance, & stability