mSCADA

Detect Production Problems 40x Faster

Your Challenge

as plant or production manager

Most of this is unavoidable, much less predictable. However, what if you could identify issues in real time and so take immediate measures to counteract them?

Production problems are painful

-

Information about problems reaches you too late

-

Troubleshooting takes too long

-

The time window for appropriate measures has already passed

-

Consequential errors can occur

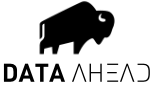

Virtually no plant or production manager can say where he really stands with his production compared to the plan. Frequently, problems in production only become known when in-house logistics or – even more annoyingly – the customer calls and asks about the products that should have left the factory long ago.

Many problems in production become known too late.

Our solution

for plant & production managers

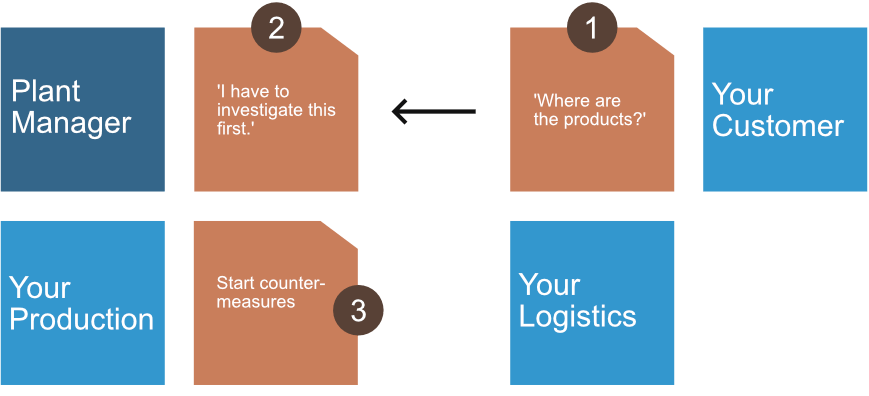

This allows you to take countermeasures in good time and focus on fixing the problems that are most important to you.

mSCADA

-

recognizes and informs you immediately about impending problems in your production

-

helps you focus on the most serious problems

-

supports you in finding the cause of the problem

-

gives you a complete view of your plant – even in the most complex manufacturing processes

-

helps you find the most efficient of your available options

-

provides immediate feedback on the measures taken

-

promotes a culture of collaboration without communication barriers

Our offer to you

So that you benefit from mSCADA right from the start, we also support you by adapting the dashboards to your individual use-case – with over 20 years of experience in industrial automation and data management, we know what is important.

mSCADA

-

No complex configuration required

-

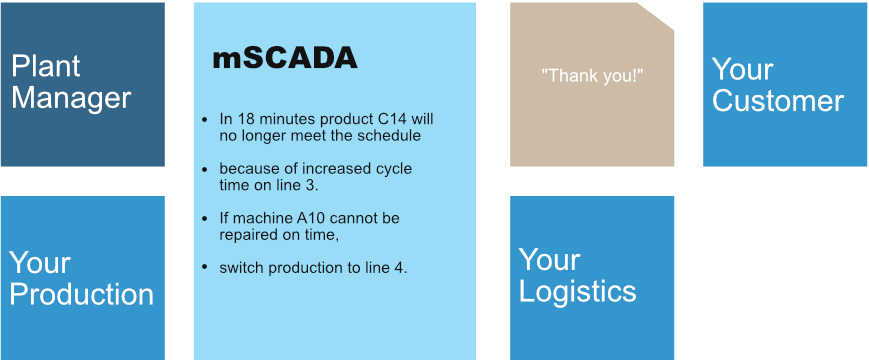

Flexible data acquisition: manual, automatic, and process data

-

More than 100 protocols available for machine connection

-

All-round support from DATA AHEAD experts

The processed data from scanners, sensors, programmable logic controllers (PLCs), and other sources are displayed on real-time dashboards. ERP or other databases can be supplied with data from mSCADA.