SPU

Program and Test Sensors Much Faster

Your Challenge

when programming and testing sensor

The number and variety of sensors continues to grow. With that, programming and teach-in time rises.

Over the past two decades, the number of sensors installed – not just in the automotive industry, but in all areas – has increased dramatically. At the same time, the variety of protocols used is proliferating.

How can the development time and production speed keep pace without painful cost inflation?

Our Solution

for fast and relaibale sensor programming

We have developed an innovative system that allows you to adjust, test, and program up to 40 sensors at the same time.

With our Sensor Programming Unit, or SPU for short, all providers along the value chain – from Tier 3 to original equipment manufacturer (OEM) – can leverage enormous savings potential.

Your advantages

-

Easy integration into existing production lines and control systems via network interfaces.

-

Flexible adaptation and expansion for different products and types thanks to real-time hardware via FPGA connection.

-

Suitable for all sensors in all industries.

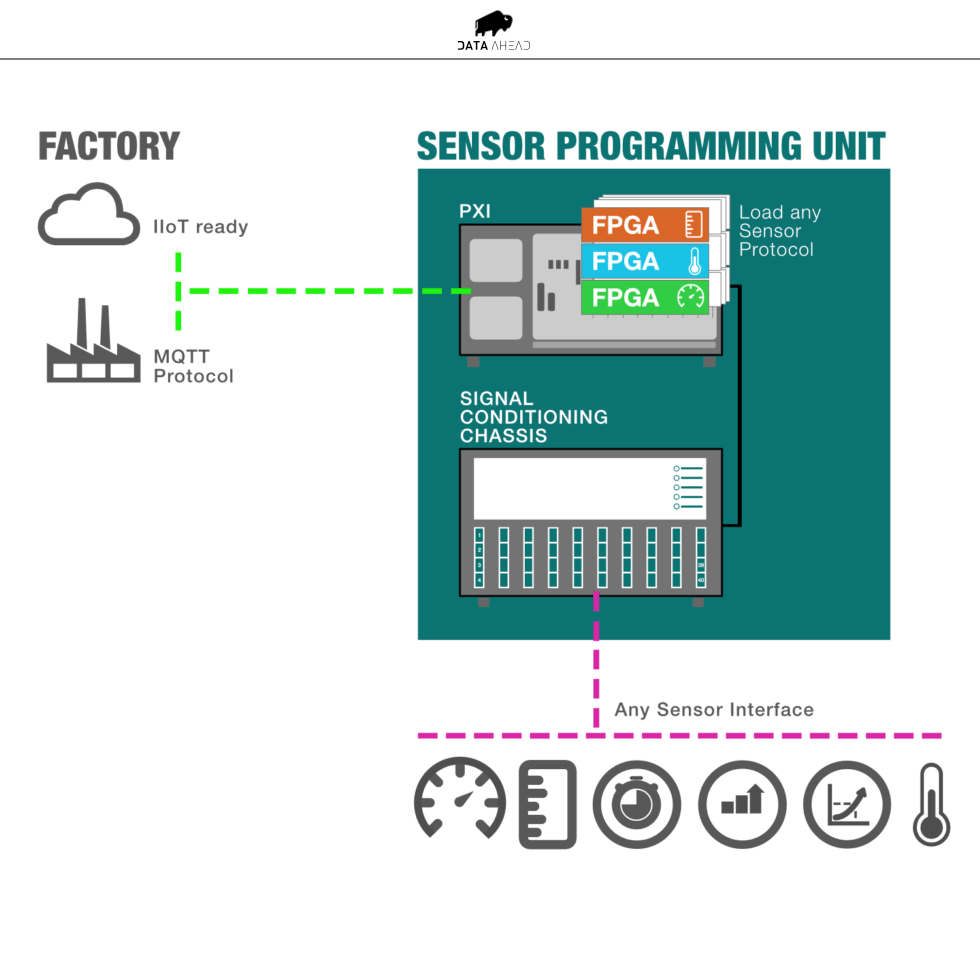

The Sensor Programming Unit at a glance

PXI

The NI PXI system with its FPGA cards is the heart of the Sensor Programming Unit. With nine slots, it offers sufficient expansion space for future test scenarios.

Signal Conditioning Chassis

The chassis can hold up to ten sensor cards, so a maximum of 40 sensors can be programmed in parallel. In addition, 40 industrial 24V DO channels are available for specific controls.

Sensor Card(s)

Each sensor card can condition signals from up to four sensors in parallel. In addition, both current and capacitance measurements can be carried out on all connected sensors.

The SPU solves these problems for you

Tier3

R&D:

Ever-shorter development cycles and increasingly complex interfaces.

Solution:

Fast adaptation through modular expansion of the sensor cards and flexible FPGA software.

Production:

Requires fast and reliable test systems.

Solution:

Highly parallelized testing.

PXI industry standard.

Tier2

Quality control:

Incoming inspection for many different products.

Solution:

Universally applicable and cost-effective expandable test equipment. Quick and easy integration into existing infrastructure.

R&D:

Development from ASIC to sensor with customer interface (SENT, LIN, etc.).

Solution:

Built-in standard protocols and easy integration of future protocols.

Production:

Calibrating and adjusting the sensors.

Solution:

Simple and inexpensive adaptation to a wide variety of ASIC interfaces.

End-of-Line-Tests (EOL):

Ever higher quality requirements from customers.

Solution:

Highly precise and permanently reliable measuring system.

Tier1 / OEM

Quality control:

Spot check.

Solution:

Complete system that is easy- and ready-to-use.

The Sensor Programming Unit in detail

PXI

-

PXI industry standard

-

Calibrated at the factory

-

Available worldwide

-

No maintenance intervals necessary

-

Modularly expandable via PXI cards

-

Scalable for higher throughput

-

Measurements:

-

Supply voltage

-

Capacity

-

Electricity

-

Sensor out

-

Communication with company systems such as production control, Line Controller, etc.

-

Industry 4.0 and cloud ready (MQTT library included)

Signal Conditioning Chassis

-

1-40 channels in parallel

-

Individual signal conditioning

-

Scalable for more parallel measurements

-

Easy maintenance

-

Reusable modules

-

Supply voltage up to 32V

Interfaces

-

All sensor types

-

Up to 40 MHz

-

Parallel operation

-

For example:

-

SENT

-

LIN

-

Manchester

-

Elmos 520.xx

-

ZSSC 4169

-

ZSSC 4151

-

ZSSC 3170

-

ZMD 3101

-

I²C

-

PWM

-

Micronas Biphase-M

-